EDI - Standing the test of time for decades

28-Aug-2025 - SCM4ALL Team

In today’s fast-moving, ever evolving world of supply chain management (SCM), where goods, information, and payments flow across the globe, Electronic Data Interchange (EDI) remains a quiet, unsung hero. For anyone curious about how supply chains keep the world’s shelves stocked and factories humming, EDI is the unsung technology ensuring it all runs smoothly. Despite newer tools like APIs, EDI’s reliability and widespread use make it the backbone of modern SCM serving ssystems. Let’s dive into its story, from its origins to its peaceful coexistence with today’s tech.

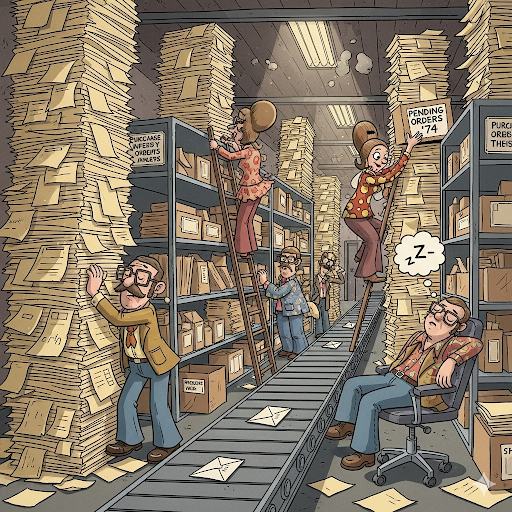

The Origins of EDI

Back in the 1960s, businesses were drowning in paperwork— stacks of purchase orders, invoices, and shipping notices. Realms and realms of faxes used to get exchanged between large organizations, with lots of people involved in sending, reviewing and interpreting them.

EDI was born to solve this, allowing companies to send these documents electronically in a standardized format. Early adopters, like railroads and grocery chains, used EDI to replace slow, error-prone paper processes with computer-to-computer communication. This was a game-changer for supply chains, cutting delays and mistakes while speeding up transactions.

Widespread Adoption in the 1990s

By the 1990s, EDI hit its stride. As global trade boomed, companies needed a way to manage complex supply chains with thousands of partners.

Standardized formats like ANSI X12 (used in North America) and EDIFACT (used globally) became the common language for business documents.

Big players like Walmart and General Motors required their suppliers to use EDI, sparking widespread adoption. This forced mass adoption, making EDI a requirement rather than a choice. By the end of the decade, it was the invisible glue holding global supply chains together.

EDI - A Fortune 500 Mainstay

Fast-forward to today, and Fortune 500 companies still rely heavily on EDI. Walmart, Target, Amazon, P&G, and logistics leaders like FedEx and UPS use EDI every day for transactions like purchase orders, shipping notices, and invoices. In many industries, especially retail and automotive, EDI isn’t optional—it’s the cost of entry.

A striking example: Walmart processes hundreds of millions of EDI transactions annually, spanning everything from socks to smartphones. Without EDI, their supply chain would grind to a halt. Similarly, automotive companies like Ford use EDI to communicate supplier schedules to thousands of tier-1 and tier-2 suppliers worldwide, ensuring parts arrive just in time.

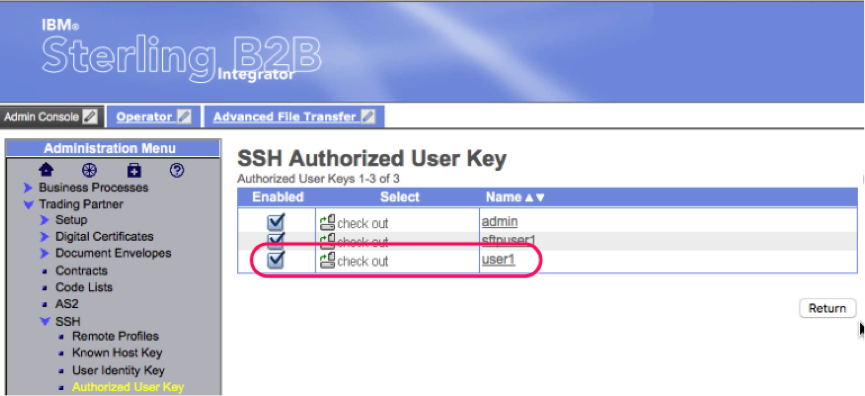

Main EDI Broker and Gateway Systems

Think of EDI as a global mail system for supply chain documents. To ensure that these “letters” get to the right place in the right format, companies rely on broker or gateway systems. These are like the post offices of the EDI world, handling the heavy lifting of sending, receiving, and translating data between partners.

Popular platforms include IBM Sterling B2B Integrator, OpenText, and Cleo.

For example, if a retailer in the U.S. sends a purchase order to a supplier in Asia, these systems ensure the data is formatted correctly, sent securely, and tracked along the way. They also catch errors—like a missing order number—before they cause delays. This works very well for the highly automated flows that most large organizations have built over the years.

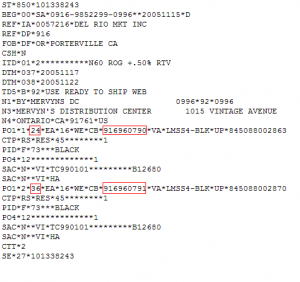

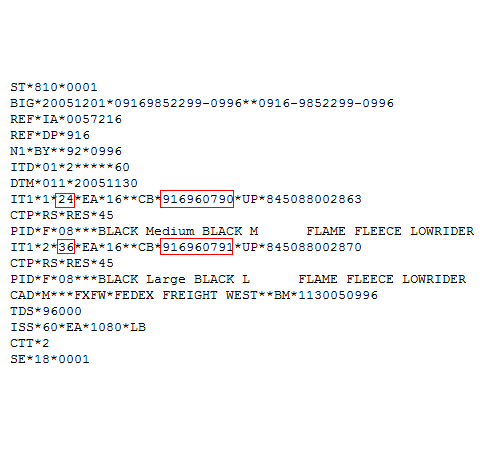

Key EDI Formats used in SCM

EDI uses specific document types, each like a standardized form for a particular job in the supply chain. Here are the main ones you’ll hear about:

850 (Purchase Order):

The retailer says, “Here’s what I want to buy,” detailing items, quantities, and prices. Example: Target sends an 850 to Procter & Gamble to order 10,000 units of detergent. The document includes quantities, delivery locations, and requested dates. No phone calls, no emails—just structured data.

855 (Purchase Order Acknowledgment):

The supplier replies, “Got your order, and I can fulfill it.” Example: P&G responds with an 855, confirming it can fulfill 9,800 units immediately and 200 units next week. Target’s systems automatically adjust inventory planning.

810 (Invoice):

The supplier sends a bill saying, “Here’s what you owe for the goods.” Example: Once those detergents are shipped, P&G issues an 810 Invoice electronically. Target’s finance system ingests it directly, enabling faster payment cycles.

856 (Advance Ship Notice):

The supplier announces, “Your order is on its way, here’s the tracking info.” Example: Before the truck leaves a P&G warehouse, an 856 is sent to Target. It tells them exactly what’s on the truck and when to expect it. Target’s distribution center schedules unloading docks in advance.

830 (Planning Schedule):

The buyer shares a forecast, like, “We’ll need 1,000 units next month.” Example: Ford sends an 830 to a seat manufacturer, forecasting that it will need 20,000 units in the next quarter. The supplier can ramp up production accordingly.

862 (Delivery Schedule):

The buyer specifies, “Deliver 200 units every Monday.” Example: Ford follows up with an 862, providing exact delivery schedules for next week: “Send 500 seats on Monday, 700 on Wednesday.” The supplier aligns production and trucks to match. These formats are like a universal language, ensuring everyone—retailers, suppliers, shippers—speaks the same terms.

EDI Baked into Corporate Workflows

For large corporations, EDI isn’t an add-on; it’s embedded into core workflows. Orders flow straight into ERP systems, shipping updates trigger warehouse movements, and invoices are reconciled automatically.

Some statistics highlight this:

-Over 80% of business-to-business (B2B) documents worldwide are exchanged via EDI.

- Walmart alone deals with more than 100,000 suppliers globally, nearly all connected via EDI.

- Automotive supply chains exchange millions of forecasts and shipping schedules weekly, enabling just-in-time manufacturing.

All this happens in seconds, with no emails or phone calls. Big companies use software like SAP or Oracle to tie EDI into their operations, automating everything from ordering to payment.

In short, EDI is the silent backbone that keeps production lines running, shelves stocked, and payments flowing.

Why EDI Stands the Test of Time

EDI isn’t new, but it’s still the backbone of SCM for good reasons:

• It’s Reliable: EDI’s standardized formats and secure systems mean data gets where it needs to go without errors. It’s like a trusty old pickup truck—maybe not flashy, but it gets the job done.

• It Scales: Whether a company handles 10 or 10,000 transactions a day, EDI can manage the load, critical for global supply chains.

• It Saves Money: By automating repetitive tasks, EDI cuts out manual data entry, saving time and reducing costly mistakes.

• It’s Universal: Standards like ANSI X12 and EDIFACT let companies worldwide talk to each other, no matter their systems.

• It’s Required: Many big players, like Walmart or Home Depot, insist suppliers use EDI, making it non-negotiable for doing business. Even as newer tech like APIs emerges, EDI’s proven track record keeps it central to SCM. It’s like the foundation of a house—new tech might add fancy rooms, but the foundation stays.

Modern APIs and EDI’s Peaceful Coexistence

Today, APIs, (Application Programming Interfaces) are the shiny new kid in SCM, offering real-time data sharing and flexibility. Unlike EDI’s structured, batch-based approach, APIs let systems talk instantly, like a live phone call versus EDI’s email. For example, an API might let a retailer check a supplier’s inventory in real-time. But APIs haven’t replaced EDI—they work alongside it. EDI excels at handling high-volume, standardized transactions, like sending thousands of purchase orders. APIs shine for dynamic tasks, like updating tracking info on a customer’s app. Many companies use both: EDI for core processes like ordering and invoicing, and APIs for real-time updates or customer-facing apps. Emerging tech like blockchain (for secure tracking) or AI (for demand forecasting) also complements EDI, not competes with it. This peaceful coexistence means EDI remains vital while new tools add flexibility to modern supply chains.

Concluding thoughts :

From its 1960s roots to its 1990s boom, EDI has grown from a paperwork-killer to the backbone of global supply chains. Used by Fortune 500 giants and powered by broker systems, EDI’s standardized formats keep orders, shipments, and payments flowing smoothly. Its reliability, scalability, and universal adoption ensure it’s still a cornerstone of SCM, even as APIs and other tech add new possibilities. For anyone curious about supply chains, EDI is the quiet force keeping the world’s goods moving—proof that sometimes, the tried-and-true is still the best.