📦 Sourcing 101: A Beginner’s Guide to Sourcing in Supply Chain Management

31-Aug-2025 - SCM4ALL Team

For anyone new to the world of Supply Chain Management (SCM), the term "sourcing" might sound simple—just buying stuff. But in a modern supply chain, sourcing is a strategic powerhouse. It's the process that determines not just how much you pay for a product, but also its quality, availability, and the resilience of your entire business. This guide will break down the fundamental terms, show you how different-sized companies handle sourcing, and reveal how data transforms this critical function.

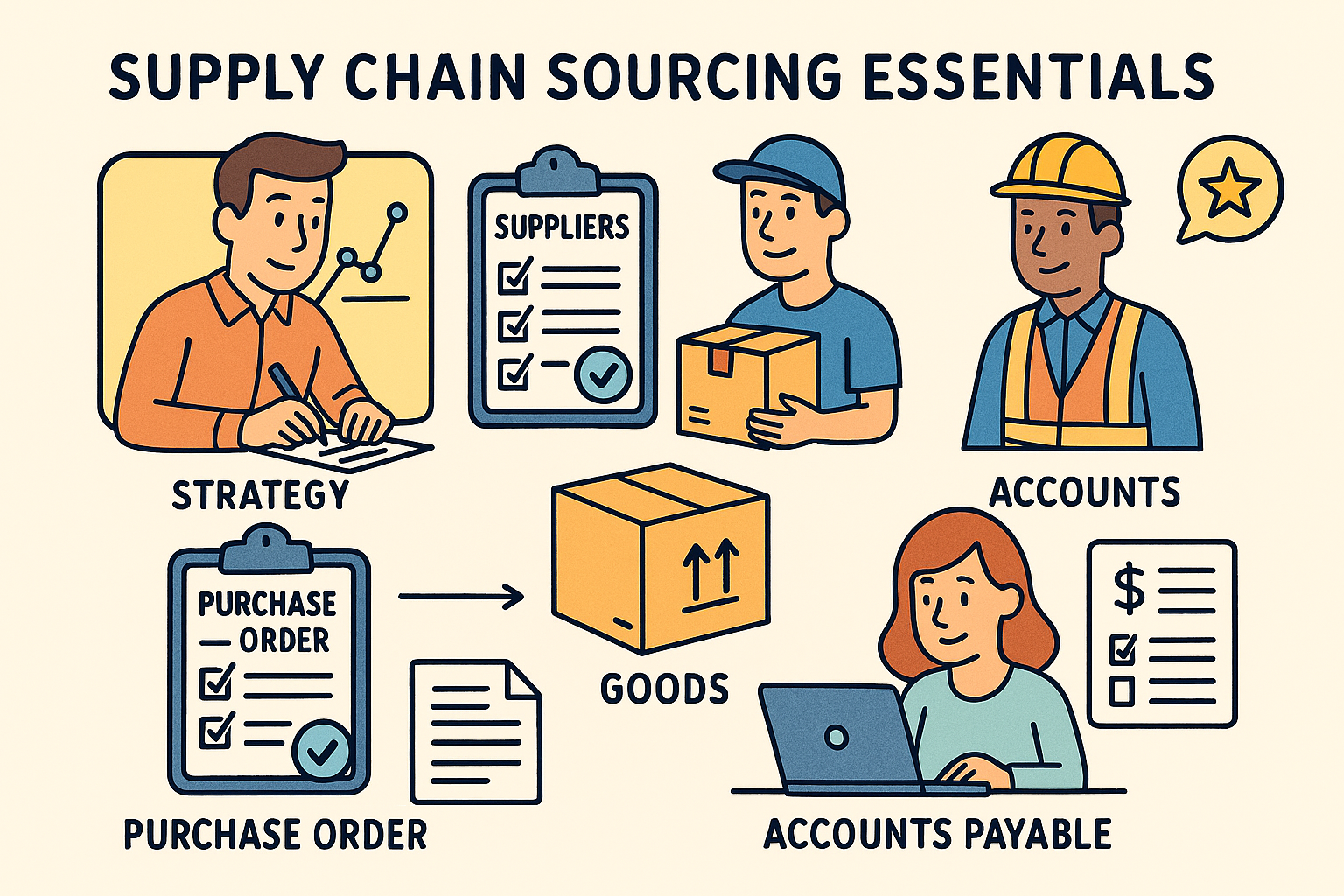

What is Supply Chain Sourcing?

Sourcing is the strategic process of identifying, evaluating, and engaging suppliers to procure the goods and services a company needs. Unlike simple purchasing, which is a transactional activity, sourcing is a long-term, strategic function that focuses on building relationships and creating value. It's about finding the "who" to supply your "what."

Key Sourcing Terms for Every SCM Learner

- Procurement: Often used interchangeably with sourcing, procurement is the broader process that includes sourcing, but also covers the entire purchasing cycle from requisition to payment. Think of sourcing as the strategic "finding" of a supplier, while procurement is the tactical "buying" from them.

- Request for Proposal (RFP): A formal document sent to potential suppliers, asking them to submit a proposal for a specific project or need. It's a key tool in competitive bidding.

- Request for Quotation (RFQ): A document used to invite suppliers to bid on specific products or services. Unlike an RFP, an RFQ is typically used when the needs are clearly defined and the main decision factor is price.

- Total Cost of Ownership (TCO): A comprehensive metric that looks beyond the initial purchase price to include all costs associated with a product or service over its entire lifecycle. This includes acquisition, maintenance, and disposal costs. A supplier with a low unit price might have a higher TCO due to poor quality or high shipping costs.

- Lead Time: The total time elapsed from the moment a purchase order is placed with a supplier to the moment the goods are received. Shorter lead times often mean a more agile supply chain.

- Lotsize: The quantity of a particular item that is ordered from a supplier in a single purchase. Sourcing teams optimize this to balance inventory costs and ordering costs.

- Economic Order Quantity (EOQ): A formula used to calculate the ideal order quantity a company should purchase to minimize inventory and ordering costs. It helps determine the most efficient lotsize.

- Blanket PO: A single purchase order that covers multiple deliveries over a period of time, used for repetitive, high-volume purchases. This is a common way to secure a fixed price for an extended period.

- Discrete PO: A one-time purchase order for a specific item or service. This is used for non-recurring or irregular purchases.

Sourcing in Practice: From Giants to Startups

Very Large Corporations (e.g., Apple, Walmart)

For a company like Apple, sourcing is a global, multi-billion dollar operation. They use strategic sourcing to manage thousands of suppliers worldwide.

- Supplier Relationships: Apple engages in deep partnerships with key suppliers like Foxconn and TSMC. They don't just buy; they co-develop technology and invest in their suppliers' manufacturing capabilities. They use Blanket POs for key components to lock in pricing and secure supply for a full year of production, for example, for iPhone parts.

- Data and Automation: Sourcing is handled by highly sophisticated, AI-powered systems. They use data analytics to monitor real-time production, geopolitical risks, and even environmental, social, and governance (ESG) factors for thousands of suppliers. This helps them manage a highly complex global supply chain and mitigate risks.

Medium Enterprises (e.g., a Regional Craft Brewery)

A medium-sized business, while not on a global scale, still uses a strategic approach.

- Supplier Network: A craft brewery will have a network of suppliers for hops, malt, yeast, and packaging. They might use a combination of local suppliers for fresh ingredients and larger national suppliers for consistent, bulk commodities. They might use a Blanket PO for their standard-issue glass bottles but use a Discrete PO for a limited-run, special edition beer.

- Negotiation & Contracts: They would likely send out RFQs for major ingredients to secure competitive pricing. They negotiate long-term contracts with key suppliers to ensure a steady, reliable supply, managing a balance between cost and quality.

Small Businesses (e.g., a Home-based Artisan)

For a small business owner, sourcing is often a more personal, hands-on process.

- Flexibility over Formalism: They might not use formal RFPs or RFQs. Instead, they rely on personal relationships, online marketplaces, and local vendors. They might buy from a single source or a handful of trusted suppliers. They will most likely use a Discrete PO for each individual order.

- Cost and Convenience: The primary drivers are often cost and convenience. They are more likely to prioritize a supplier who offers good prices and reliable shipping, as they have limited time and resources.

The Data-Driven Flow of Sourcing

Data is the lifeblood of modern sourcing. The flow of information is as critical as the flow of goods.

- Needs Identification: The process starts with a need, often triggered by a Purchase Requisition from a department or a forecast from inventory planning. This data includes what is needed, the quantity, and when it's needed.

- Supplier Discovery: Sourcing teams use internal spend data and external market data (e.g., commodity prices, geopolitical reports) to identify potential suppliers.

- Bidding & Evaluation: Information flows back and forth as companies send out RFPs/RFQs and receive bids. This data is rigorously analyzed using scorecards to evaluate suppliers on criteria beyond price, such as quality, lead time, and sustainability.

- Purchase Order (PO) Creation: Once a supplier is selected, a Purchase Order is created. This document is a critical data point that formalizes the transaction.

- Performance Monitoring: Real-time data from a supplier's warehouse (via EDI or integrated systems) provides visibility into inventory levels, production schedules, and shipping status.

Types of Suppliers

Suppliers can be categorized in many ways, but a common approach is based on their strategic importance to the business.

- Bottleneck Suppliers: Few alternatives, high risk. Think of a unique chemical compound required for a specialized medicine.

- Strategic Suppliers: High value, high risk. These are the partners a company relies on for its core products, like TSMC for Apple's processors.

- Leverage Suppliers: Many alternatives, high value. These are suppliers of commodities where a company has a lot of buying power, like a major food company buying corn.

- Non-Critical Suppliers: Many alternatives, low value. Think of office supplies.

Key Sourcing Metrics

Companies measure sourcing success using a variety of metrics:

| Metric | Description | Why it Matters |

|---|---|---|

| Supplier On-Time Delivery (OTD) | The percentage of orders delivered on or before the promised date. | Indicates supplier reliability and impacts production schedules and customer satisfaction. |

| Supplier Quality Rate | The percentage of materials or products that meet quality standards. | Directly affects product quality, returns, and manufacturing waste. |

| Cost Savings | The monetary value saved through sourcing activities (e.g., negotiating better prices). | A key measure of the sourcing team's direct contribution to the company's bottom line. |

| Purchase Order (PO) Cycle Time | The time it takes from a PO being created to the goods being received. | A shorter cycle time indicates an efficient process and better responsiveness. |

| Total Cost of Ownership (TCO) | The true long-term cost of a product, including purchase price, shipping, quality, and maintenance. | Enables informed decisions by looking beyond the initial price tag. |

The Purchase Order (PO) Lifecycle

The PO is the foundational document of sourcing. Its lifecycle follows a clear path:

- Requisition: A department identifies a need and creates an internal request.

- PO Creation: The procurement team creates the PO, detailing the items, price, terms, and delivery date. This could be a Blanket PO for recurring needs or a Discrete PO for a one-off purchase.

- PO Approval: A manager or finance team reviews and approves the PO to ensure it aligns with the budget.

- PO Dispatch: The approved PO is sent to the supplier, often electronically.

- Supplier Acknowledgment: The supplier confirms receipt and acceptance of the order.

- Goods Receipt: The goods arrive, and a "Goods Receipt" document is created, confirming the delivery.

- Invoice & Payment: The supplier sends an invoice, which is matched to the original PO and Goods Receipt (a process called "3-way matching"), and payment is released.

How Sourcing Data Drives Improvement

Companies use the vast data generated by the sourcing process to get better over time.

- Risk Management: By analyzing supplier performance data, a company can identify and mitigate risks. If a supplier's On-Time Delivery rate drops, the company can proactively reach out to understand the issue before it causes a major disruption.

- Demand Forecasting: Sourcing data on historical purchases and supplier lead times helps improve the accuracy of demand forecasts, ensuring the right amount of stock is on hand.

- Process Optimization: Analyzing PO Cycle Time can reveal bottlenecks in the approval process, allowing a company to streamline workflows and reduce the time it takes to get products.

- Cost Reduction: By leveraging TCO data, a company can make informed decisions. They might switch from a low-cost, low-quality supplier to a slightly more expensive but higher-quality one, realizing long-term savings from reduced returns and less waste. Using data to optimize Lotsize based on EOQ can also lead to significant savings.

Conclusion

Sourcing is far more than a simple transaction. It is a strategic discipline that, when executed with data and foresight, builds resilient, cost-effective, and competitive supply chains. By mastering these core terms and understanding the strategic choices made by companies of all sizes, you’re well on your way to becoming an SCM expert.