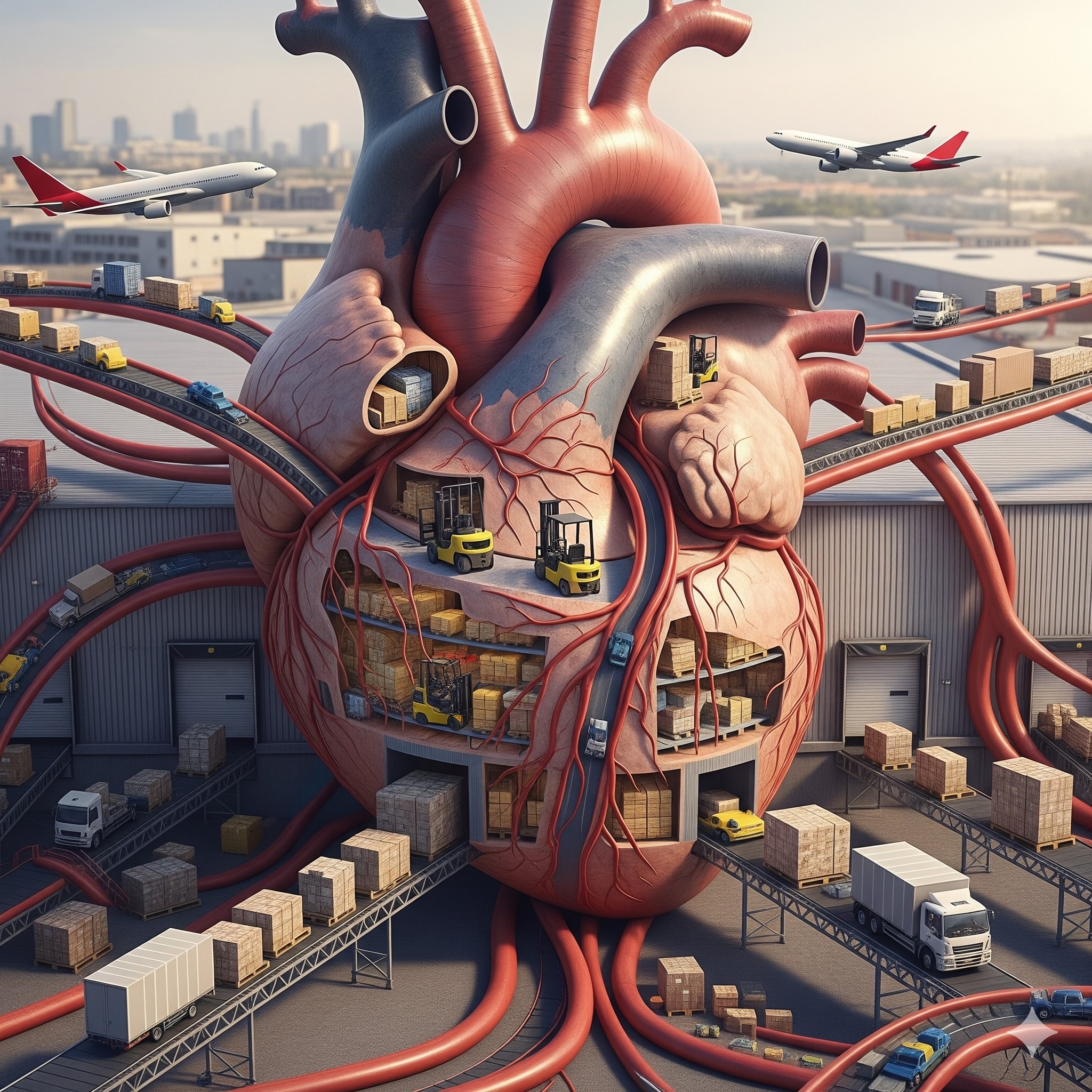

Logistics : The veins and arteries of Supply Chain

12-Sep-2025 - SCM4ALL Team

A deep dive into the strategic importance, key players, and future of moving goods in the global economy.

In today's interconnected global economy, the movement of goods is the heartbeat of commerce. From the raw materials sourced across continents to the final product delivered to your doorstep, logistics and transportation are the unsung heroes orchestrating this intricate dance. Far more than just moving boxes, these two pillars of Supply Chain Management (SCM) are critical for efficiency, cost-effectiveness, and, ultimately, customer satisfaction.

Let's unpack the vital role of logistics and transportation, exploring its types, challenges, future, and real-world applications.

The Foundation: Why Logistics is Essential to Your Business

Logistics is the comprehensive process of planning, implementing, and controlling the efficient flow and storage of goods, services, and related information from the point of origin to the point of consumption. It’s the strategic arm of the supply chain, ensuring that the right product is in the right place, at the right time, and in the right condition. Its importance in SCM is multi-faceted:

- Cost Reduction: Optimized logistics minimizes expenses related to freight, warehousing, inventory holding, and even packaging.

- Enhanced Customer Satisfaction: Timely, accurate, and reliable delivery, coupled with efficient returns, builds trust and customer loyalty.

- Competitive Advantage: Companies with superior logistics can offer faster delivery, wider product availability, and more reliable service, setting them apart in the market.

- Global Market Access: Effective logistics enables businesses to source materials and sell products worldwide, unlocking vast opportunities.

The Pathways of Progress: Types of Transportation

The choice of transportation mode is a strategic decision that fundamentally impacts a company’s speed, cost, and capacity. Here are the primary types and their applicability:

-

Road Transport (Trucking):

Applicability: Unmatched flexibility for door-to-door delivery. It is ideal for shorter distances, last-mile delivery, and a wide array of goods from consumer products to industrial components.

Example: A local distributor delivering fresh produce to grocery stores daily, or an e-commerce company fulfilling individual customer orders.

-

Rail Transport:

Applicability: Highly cost-effective for bulk goods and heavy shipments over long, inter-city or inter-state distances. Best for raw materials (e.g., coal, grain), automobiles, and intermodal containers.

Example: Transporting thousands of tons of timber from a logging region to a processing plant across the country.

-

Water Transport (Shipping):

Applicability: The most economical mode for large volumes of goods over vast international distances. Essential for global trade of raw materials, oil, manufactured goods, and heavy machinery.

Example: A mega container ship carrying electronics, apparel, and furniture from Asian manufacturing hubs to European and North American ports.

-

Air Transport:

Applicability: The fastest option, indispensable for high-value, time-sensitive, and perishable goods. Critical for pharmaceuticals, urgent spare parts, luxury items, and fresh flowers.

Example: Rushing a batch of life-saving vaccines or newly launched smartphones to global markets to meet demand.

-

Pipeline Transport:

Applicability: Highly efficient and specialized for the continuous flow of liquids and gases. Primarily used for crude oil, natural gas, refined petroleum products, and sometimes water.

Example: A vast network of pipelines delivering natural gas from production fields to homes and power plants.

Decoding the Jargon: Essential SCM Terms in Logistics & Transportation

Understanding the lexicon of logistics is key to navigating the supply chain. Here are some of the main terms:

- Freight: Any goods, cargo, or commodities transported for a fee.

- Carrier: The company or entity responsible for transporting goods (e.g., a trucking company, airline, shipping line).

- Consignee: The ultimate recipient of a shipment.

- Shipper/Consignor: The party initiating the shipment of goods.

- Bill of Lading (BOL): A legal document issued by the carrier to the shipper, serving as a receipt of freight services and a contract of carriage.

- Customs Clearance: The process of obtaining permission from customs authorities to import or export goods, involving duties and taxes.

-

Third-Party Logistics (3PL): An external company that a business outsources its logistics operations to, including transportation, warehousing, and often inventory management.

Example: A small apparel brand outsourcing all its distribution, from warehouse storage to final customer delivery, to a specialized 3PL.

- Fourth-Party Logistics (4PL): A higher-level integrator that manages the entire supply chain for a client, often by overseeing multiple 3PLs and other service providers. A 4PL acts as a logistics consultant and orchestrator.

- Inbound Logistics: The management of raw materials and components flowing into a company's production or assembly facilities.

- Outbound Logistics: The management of finished products flowing out of a company to its customers.

- Reverse Logistics: The process of managing the return of products, including returns, repairs, recycling, or disposal.

The Interconnected Web: Logistics' Ties to Other SCM Factors

Logistics and transportation are not isolated functions; they are deeply interdependent with other SCM elements:

- Warehousing: Efficient transportation relies heavily on well-managed warehouses. Warehouses serve as crucial nodes for receiving, storing, picking, packing, and preparing goods for outbound shipment. Delays in warehousing directly translate to transportation bottlenecks.

- Product Type: The nature of the product dictates the transportation strategy. Perishable goods require cold chain logistics (refrigerated transport), while delicate electronics demand specialized handling and packaging.

- Costs: Companies must balance the cost of transportation with other SCM costs. Faster shipping (e.g., air freight) is more expensive but can reduce inventory holding costs by allowing for a leaner supply chain.

- Location: Geographical location and network design are critical. A company's proximity to a port, airport, or major highway determines which modes of transport are most feasible and cost-effective.

Optimizing Routes: What is a "Milk Run"?

A Milk Run is a highly efficient logistics strategy where a single vehicle collects or delivers goods to multiple suppliers or customers along an optimized, predetermined route. The concept is named after the traditional milkman's route, where the truck would deliver milk and pick up empty bottles from multiple houses. This strategy consolidates movements, significantly reducing fuel consumption, mileage, and labor costs compared to individual, point-to-point trips.

Example: An automotive assembly plant sends one truck on a route to pick up engine parts from Supplier A, then tires from Supplier B, and then electronic components from Supplier C, all located within the same industrial zone, before returning to the plant.

The Future is Now: Disruptions in Logistics & Transportation

The coming decades promise unprecedented transformation, driven by technology:

- Hyperlocal with Drones: Imagine ordering fresh groceries or urgent medical supplies and having them delivered by autonomous drones directly to your backyard or balcony within minutes. This will revolutionize last-mile delivery, especially in urban areas, offering unparalleled speed and reducing road congestion.

- AI Disrupting Transportation: Artificial Intelligence will be a game-changer:

- Dynamic Route Optimization: AI algorithms will constantly analyze traffic, weather, and delivery priorities to dynamically adjust routes in real-time, drastically improving efficiency.

- Predictive Maintenance: AI will forecast equipment failures in vehicles and machinery, enabling proactive maintenance and minimizing costly downtime.

- Autonomous Vehicles: Self-driving trucks, delivery robots, and automated forklifts will become commonplace, addressing labor shortages, improving safety, and enabling 24/7 operations.

- Automated Warehousing: AI-powered robotics will streamline everything from picking and packing to loading and unloading, creating hyper-efficient warehouses.

Global Giants: Companies Focused on Logistics & Transportation

While many companies have logistics as a component, some have made it their entire business model. These are the giants who have made the movement of goods their core competency:

-

DHL Group (Deutsche Post DHL Group)

What Sets Them Apart: The most globally integrated logistics provider, operating in over 220 countries and territories. Their comprehensive, end-to-end service offering includes express delivery, freight forwarding, and contract logistics. What truly distinguishes them is their ability to handle everything from a single envelope to the entire supply chain of a multinational corporation.

Approx. Yearly Revenue (2024): ~$94.1 billion USD.

Footprint: A massive network of air and ground hubs, with a presence in virtually every corner of the globe, including Europe, the Americas, Asia Pacific, and Africa.

-

FedEx Corporation

What Sets Them Apart: FedEx is synonymous with expedited shipping and reliability, a reputation it built by pioneering the overnight shipping model. Their key differentiator is their extensive and highly efficient air network, which gives them a significant advantage in express delivery and international shipping. Their "hub-and-spoke" model allows them to handle massive volumes of packages with incredible speed.

Approx. Yearly Revenue (FY2024): ~$87.7 billion USD.

Footprint: An extensive global air and ground network serving over 220 countries and territories, with a primary air hub in Memphis, Tennessee, that is one of the world's busiest cargo airports.

-

A.P. Moller – Maersk

What Sets Them Apart: Maersk's defining characteristic is its strategic transition from a pure container shipping company to an "integrated container logistics company." While they operate the world's largest fleet of container vessels, they now offer end-to-end supply chain solutions, including landside transportation, warehousing, and customs brokerage. This allows them to provide a seamless, simplified experience for their customers.

Approx. Yearly Revenue (2024): ~$55.5 billion USD.

Footprint: Operates in over 130 countries with a global fleet of container vessels, ports, and an expanding network of over 500 distribution centers and logistics facilities.

Case Studies: Tailored Logistics Strategies

The best logistics strategy is one that is custom-built for a company’s unique needs.

-

New Chinese Tablet Company:Imagine we have a new entrant in the tablet/hand-held space, looking to get a foothold into the market. What would their logistics strategy look like ?

- Inbound Strategy (China to Europe/USA):

- Initial Phase: Start with air freight for small, initial shipments. While expensive, this provides speed and flexibility for a new product with unpredictable demand, minimizing inventory risk and allowing for quick market testing.

- Scale-up: As demand becomes more predictable, shift the bulk of shipments to more economical sea freight (container shipping) to reduce costs per unit.

- Outbound Strategy (Within Europe/USA to Customers):

- Partner with a 3PL: The most effective strategy is to outsource all outbound logistics to an established Third-Party Logistics (3PL) provider. The 3PL will handle warehousing, order fulfillment, and last-mile delivery. This allows the new company to avoid massive capital investment in infrastructure and focus on its core competency: product development and marketing.

- Inbound Strategy (China to Europe/USA):

-

100-Year-Old Nashville Bakery: We have a bakery, strong legacy, 100% sales through their well established brick and mortar storefront. What if they want to move with the times and now include online deliveries too, what would their logistics strategy likely look like ?

- Inbound Strategy:

- Maintain Existing System: The bakery’s century of experience means its inbound logistics for raw materials (flour, sugar, etc.) is likely highly optimized. The company should largely maintain its current system with existing suppliers.

- Dynamic Forecasting: The only adjustment needed is to incorporate new demand data from online orders into its raw material forecasting to ensure it has enough ingredients for the new sales channel.

- Outbound Strategy:

- Hybrid Model: A combination of two strategies is required due to the perishable and delicate nature of the product.

- Local Deliveries: For customers within the Nashville metro area, use in-house delivery drivers or a dedicated local courier service. This offers the highest level of control over product quality and provides a personal touch that aligns with the bakery's brand.

- Regional/National Shipping: For customers outside the local area, partner with a specialized carrier like FedEx or UPS, but only using their expedited shipping options (e.g., overnight or 2-day delivery). This requires an investment in high-quality, insulated packaging with gel packs to ensure the product arrives fresh and intact.

- Hybrid Model: A combination of two strategies is required due to the perishable and delicate nature of the product.

- Inbound Strategy:

Concluding Takeaways

In essence, logistics and transportation are the strategic backbone of any modern supply chain, transforming from a simple operational task into a critical competitive advantage. The choice of transport mode, from air to sea, must be meticulously aligned with a product's type and market demands, while technology, particularly AI and automation, is poised to revolutionize the entire process. Ultimately, successful companies view logistics not as a cost to be minimized, but as a dynamic and data-driven system to be optimized for maximum efficiency, resilience, and customer satisfaction.