The Heartbeat of the Supply Chain: A Deep Dive into Warehousing

6-Sep-2025 - SCM4ALL Team

In the complex and fast-paced world of Supply Chain Management (SCM), a warehouse is far more than just a place to store goods. It is a dynamic hub of activity, a critical node that ensures products move efficiently and accurately from a supplier to a customer. This blog post will explore the fundamental role of warehousing, its different forms, key operations, and the technological innovations that are shaping its future.

- What is Warehousing?

- Types of Warehouses

- Bonded vs. Non-Bonded

- Micro Fulfillment & Dark Stores

- Main Operations

- Main Warehouse KPIs

- Warehousing Technology

- Amazon Case Study

- Location Considerations

- Future of Warehousing

What is Warehousing and Why is it Important?

At its core, warehousing is the process of storing goods and materials before they are distributed to their final destination. It's a crucial component of the supply chain that provides a buffer between production and consumption. The importance of a well-managed warehouse cannot be overstated. It ensures:

- Inventory Management: Warehouses allow companies to manage stock levels effectively, preventing both stockouts and overstocking. This is vital for maintaining a steady flow of goods and managing costs.

- Order Fulfillment: They are the central point for receiving, picking, packing, and shipping customer orders, directly impacting customer satisfaction and delivery times.

- Value-Added Services: Modern warehouses offer more than just storage. They can provide services like kitting, labeling, and light assembly, adding value to the products before they are shipped.

- Risk Mitigation: Storing inventory in a secure, controlled environment protects goods from damage, theft, and spoilage, especially for perishable or high-value items.

A Spectrum of Storage: Different Types of Warehouses

Not all warehouses are created equal. The type of warehouse a company uses is heavily dependent on its business model, industry, and the nature of its products.

- Public Warehouses: Owned by a third party, these warehouses offer flexible storage space to multiple businesses. They are often used by small or growing companies that don't have the capital to invest in a private facility.

- Private Warehouses: Owned and operated by a single company for its exclusive use. Large businesses with a high volume of inventory, like a manufacturer or a major retailer, often opt for a private warehouse to maintain full control over their operations.

- Distribution Centers: Unlike traditional warehouses that focus on long-term storage, distribution centers are designed for high-throughput, rapid movement of goods. They receive large shipments and quickly sort and dispatch them to retailers. A Kroger grocery distribution center, for example, would be a high-velocity operation, moving fresh produce and consumer packaged goods to local supermarkets multiple times a day.

- Fulfillment Centers: These are a type of distribution center specifically focused on direct-to-consumer (D2C) order fulfillment, a model made popular by e-commerce. Amazon's massive facilities are prime examples. They handle a vast variety of individual orders for a diverse customer base.

- Cold Storage Warehouses: These are temperature-controlled facilities used for storing perishable goods like food, pharmaceuticals, and certain chemicals. This is a critical requirement for a company like a major food distributor.

Bonded vs. Non-Bonded Warehouses

- Bonded Warehouse: A bonded warehouse is a secure facility authorized by customs authorities to store imported goods. The key advantage is that duties and taxes are deferred until the goods are officially released for sale or re-exported. This is a massive cash flow benefit for companies dealing with international trade. For a company importing high-value electronics into the EU via a port in Belgium, a bonded warehouse allows them to hold products, assess market demand, and only pay the required duties when the goods are ready to be shipped to retail outlets across Europe.

- Non-Bonded Warehouse: This is a standard storage facility where all customs duties and taxes have already been paid. It is used for domestic storage and distribution. Once the electronics company pays the duties on its imported goods in Belgium, it can move them to a non-bonded warehouse for final distribution to stores within the country.

The Rise of Urban Warehousing: Micro Fulfillment and Dark Stores

As e-commerce demand for same-day and one-hour delivery has surged, new, smaller-scale warehousing models have emerged.

- Micro Fulfillment Centers (MFCs): These are compact, highly automated warehouses often located within or near existing retail stores in urban areas. They use robotics and automated systems to rapidly pick and pack online orders for ultra-fast delivery. Think of a small automated hub inside a city supermarket designed to handle all online grocery orders.

- Dark Stores: These are traditional retail locations that have been converted into dedicated fulfillment hubs. They are closed to the public and redesigned for efficient order picking and packing. They leverage the existing store footprint in a strategic location to serve online customers.

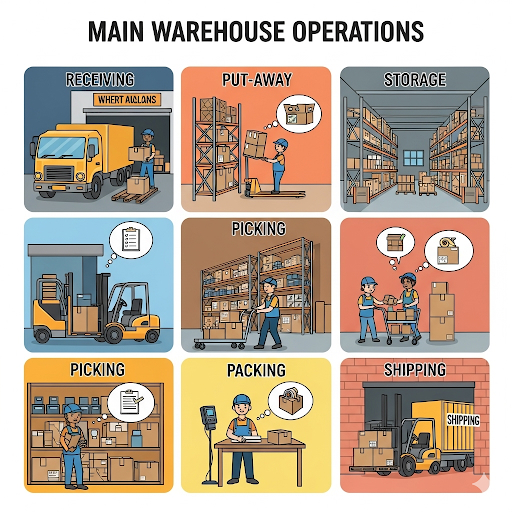

A Glimpse into the Warehouse Floor: Core Operations

A warehouse is a hive of activity, and its success hinges on the efficiency of its core operations. These typically include:

- Receiving: The first step, where incoming goods are unloaded, inspected for damage, and verified against a purchase order.

- Put-Away: The process of moving received goods from the receiving area to their designated storage location.

- Storage: The organization and management of inventory within the warehouse to optimize space and accessibility.

- Picking: The retrieval of items from their storage locations to fulfill a specific customer or store order. This can be done manually or with the help of technology.

- Packing: Preparing the picked items for shipment, including packaging, labeling, and adding any necessary documentation.

- Shipping: The final step where the packed orders are loaded onto transportation vehicles and dispatched for delivery.

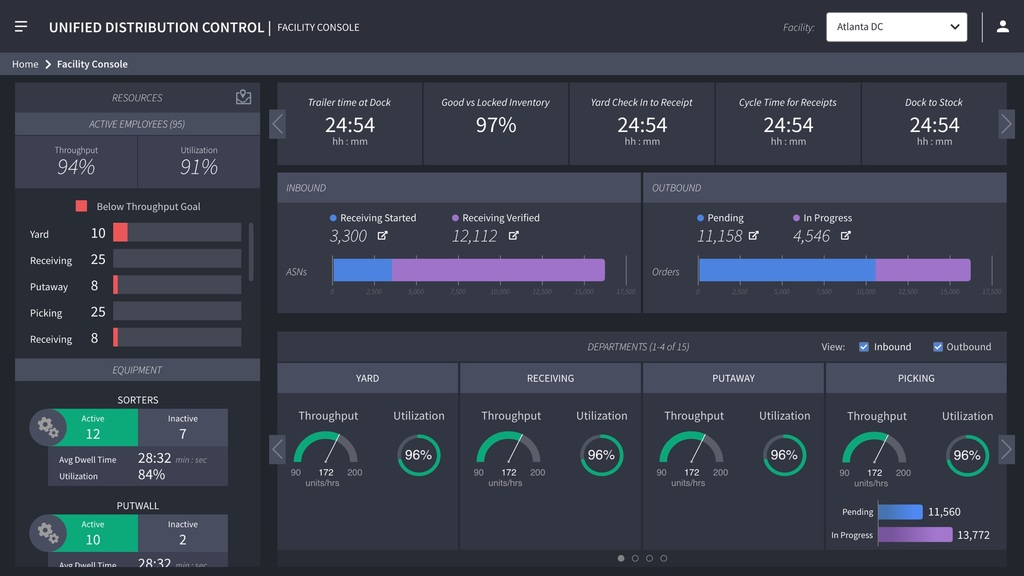

Measuring Success: Key Performance Indicators (KPIs)

To ensure a warehouse operates at peak efficiency, managers track a range of key performance indicators (KPIs). Some of the most critical include:

- Receiving Efficiency: Measures the time it takes to process and put away incoming inventory.

- Picking Accuracy: The percentage of orders picked without error. This directly impacts customer satisfaction.

- Order Cycle Time: The total time from when an order is placed to when it is delivered to the customer.

- Inventory Turnover: A measure of how many times a company's inventory is sold and replaced over a period. A high turnover rate is generally desirable.

- On-Time Shipping Rate: The percentage of orders that are shipped on or before the promised date.

- Carrying Cost of Inventory: The total cost of holding inventory, including storage, insurance, and obsolescence.

Tech Integrated with most Modern Warehouses

Modern warehouses are a testament to the power of technology. Automation and data-driven systems have transformed operations, leading to unprecedented levels of efficiency and accuracy.

- Warehouse Management Systems (WMS): These software solutions are the brains of the modern warehouse. They manage and track all operations, from inventory levels and order processing to labor management and shipping.

- Automation & Robotics:

- Automated Storage and Retrieval Systems (AS/RS): Computer-controlled systems that automatically place and retrieve items from storage racks.

- Autonomous Mobile Robots (AMRs): These intelligent robots navigate the warehouse floor to transport goods, assist with picking, and move shelves of products to human workers, a model famously pioneered by Amazon.

- Drones: Used for quick and accurate inventory counts, scanning barcodes from high-up shelves.

- Internet of Things (IoT): Sensors and RFID (Radio-Frequency Identification) tags on products and equipment provide real-time data, enabling live tracking of inventory and assets.

- Predictive Analytics: Using historical data and machine learning, companies can forecast demand more accurately, optimize inventory placement, and plan for seasonal spikes.

Amazon : A trailblazer in Warehouse Automation

Amazon has revolutionized warehousing and logistics with its aggressive investment in automation. The company's acquisition of Kiva Systems (now Amazon Robotics) was a game-changer. Rather than human workers walking miles of aisles to find products, the orange Kiva robots lift and transport entire shelves to a stationary picker. This "goods-to-person" model dramatically reduces walking time, increases picking speed, and boosts overall productivity.

Beyond the Kiva robots, Amazon's warehouses utilize a range of other automated technologies, including robotic arms for sorting and packing, and sophisticated software that orchestrates every movement. This high level of automation allows Amazon to handle a staggering volume of orders, offering services like Prime two-day and same-day delivery, setting a new standard for the entire e-commerce industry.

Warehouse Location: A Strategic Decision

The physical location of a warehouse is a critical strategic decision that impacts costs, delivery times, and overall supply chain efficiency. Key factors to consider include:

- Proximity to Customers: For retail and e-commerce, being close to population centers is vital for achieving fast delivery times and reducing last-mile transportation costs.

- Proximity to Suppliers: For manufacturers, a warehouse near key suppliers can reduce inbound transportation costs.

- Labor Availability: Access to a skilled workforce is essential for running a productive warehouse, especially for facilities that are not fully automated.

- Transportation Infrastructure: Easy access to major highways, railways, seaports, or airports is crucial for efficient inbound and outbound logistics.

Think about the different needs of various industries. A Boeing warehouse, which stores massive aircraft parts, would need to be located near its manufacturing plant or a major airport, with access to specialized transportation. In contrast, an Apple warehouse, holding high-value, small-footprint electronics, would likely be situated near a major international airport for fast global distribution. A Toyota parts distribution center would be strategically placed to quickly supply a network of dealerships and repair shops across a region.

The Future is Intelligent: AI and the Warehouse

The future of warehousing is inextricably linked with artificial intelligence (AI). AI is moving beyond simple automation to create a truly intelligent, self-optimizing warehouse.

- Predictive Maintenance: AI algorithms analyze data from machinery to predict when equipment will fail, allowing for proactive maintenance and preventing costly downtime.

- Optimized Operations: AI can analyze vast datasets to optimize warehouse layout, suggest the most efficient picking paths, and even determine the perfect box size for a shipment, reducing waste and shipping costs.

- Smarter Robots: The next generation of robots will be even more intelligent, using AI and machine learning to handle more complex, non-repetitive tasks with greater precision and autonomy.

- Enhanced Visibility: AI will provide unprecedented real-time visibility into the entire supply chain, allowing for proactive problem-solving and dynamic rerouting of shipments to avoid disruptions.

In conclusion, warehousing is a cornerstone of modern commerce. As consumer demands for speed and efficiency grow, the warehouse will continue to evolve, leveraging technology and intelligent systems to become an even more sophisticated and indispensable part of the global supply chain.